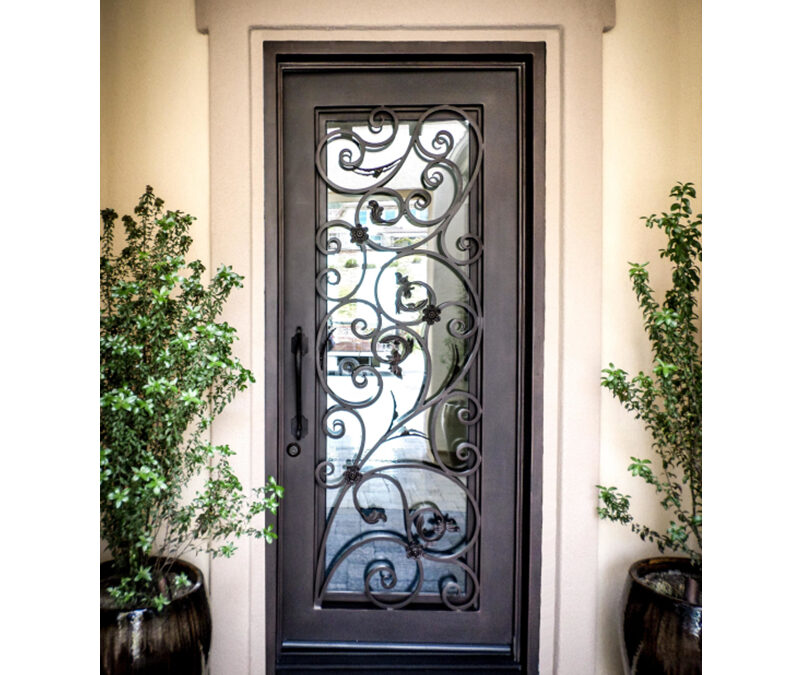

Cleaning your wrought iron door is important for maintaining its appearance and prolonging its lifespan.

Here are some steps to follow for cleaning your wrought iron door:

Remove loose dirt and debris: Use a soft-bristled brush or a dry cloth to remove any loose dirt or debris from the surface of the door. This will make it easier to clean the door thoroughly.

Prepare a cleaning solution: Mix a mild soap, such as dish soap, with warm water in a bucket. You can also use a specialized cleaner designed for wrought iron doors, which can be found at your local hardware store.

Apply the cleaning solution: Dip a soft-bristled brush or a sponge in the cleaning solution and apply it to the surface of the door. Scrub the door gently, working in small sections at a time, to remove dirt, grime, and other debris.

Rinse the door: Use a hose or a bucket of clean water to rinse the door thoroughly. Be sure to remove all of the cleaning solution to prevent it from leaving streaks or residue on the surface of the door.

Dry the door: Use a soft cloth or a towel to dry the door completely. Be sure to remove all of the moisture from the surface of the door to prevent rust or corrosion from developing.

Apply a protective coating: Once the door is dry, apply a protective coating, such as a rust inhibitor or sealant, to help prevent rust and corrosion from developingon the surface of the door. Follow the manufacturer’s instructions for proper application and drying time.

Inspect for damage: After cleaning and drying the door, inspect it for any signs of damage, such as cracks, chips, or rust spots. how to clean wrought iron door Address any damage as soon as possible to prevent it from getting worse.

By following these steps, you can help keep your wrought iron door clean and protected, and ensure that it remains beautiful and functional for many years to come.

What type of protective coating do you recommend?

There are several types of protective coatings that you can use on your wrought iron door to help prevent rust and corrosion and extend its lifespan.

Here are some of the most common types of protective coatings for wrought iron doors:

Powder coating: Powder coating is a popular choice for wrought iron doors because it offers a durable and long-lasting finish. It involves applying a dry powder to the surface of the door, which is then heated to form a hard, protective layer. Powder coating is available in a variety of colors and finishes, and it is resistant to chipping, fading, and scratching.

Epoxy coating: Epoxy coating is a two-part coating that is applied to the surface of the door in a liquid form and then hardens into a durable and long-lasting finish. Epoxy coatings are resistant to moisture, chemicals, and abrasions, making them a good choice for wrought iron doors that are exposed to harsh weather conditions or heavy use.

Enamel coating: Enamel coating is a type of paint that is specifically designed for use on metal surfaces. It provides a glossy and durable finish that is resistant to rust, corrosion, and fading. Enamel coatings are available in a variety of colors and finishes, and they can be applied using a brush, roller, or spray gun.

Rust inhibitor: Rust inhibitors are a type of protective coating that are designed to prevent rust and corrosion from developing on metal surfaces. They are available in a variety of forms,including sprays, liquids, and waxes, and they work by creating a barrier between the metal surface and the elements. Rust inhibitors are a good choice for wrought iron doors that are located in areas with high levels of humidity or exposure to moisture.

When choosing a protective coating for your wrought iron door, consider factors such as the climate conditions in your area, the level of exposure to moisture and other elements, and your aesthetic preferences. It is also important to follow the manufacturer’s instructions for proper application and maintenance of the coating to ensure its effectiveness and longevity.