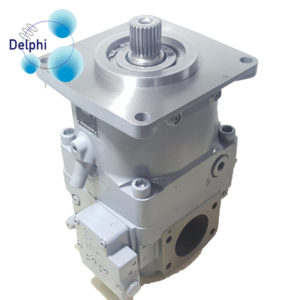

The Rexroth A4VSO pump is a type of axial piston variable pump that is commonly used in hydraulic systems. Like any hydraulic pump, the A4VSO pump contains several parts that work together to create a flow of hydraulic fluid under pressure.

Here are some common parts of the Rexroth A4VSO pump:

Cylinder block: The cylinder block contains the axial pistons and swash plate that are used to create the flow of hydraulic fluid.

Pistons: The axial pistons rotate around the central shaft of the pump and create the flow of hydraulic fluid.

Swash plate: The swash plate is mounted on the central shaft and can be tilted to adjust the angle of the pistons, rexroth a4vso pump parts thereby adjusting the flow rate and pressure of the hydraulic fluid.

Valve plate: The valve plate is used to control the flow of hydraulic fluid into and out of the pump, allowing the pump to adjust to changes in the hydraulic system’s flow and pressure requirements.

Shaft seal: The shaft seal is used to prevent hydraulic fluid from leaking out of the pump along the central shaft.

Bearings: The bearings are used to support the rotating components of the pump, including the central shaft and pistons.

Housing: The housing contains the various components of the pump and provides support and protection for the pump.

If any of these parts become worn or damaged, it can affect the performance of the pump and lead to downtime and reduced efficiency. It’s important to use genuine Rexroth replacement parts when repairing or maintaining the A4VSO pump to ensure optimal performance and reliability. Rexroth offers a range of replacement parts for the A4VSO pump, including cylinder blocks, pistons, swash plates, valve plates, shaft seals, bearings, and housings.

Proper maintenance is essential to keep the Rexroth A4VSO pump running smoothly and efficiently.

Here are some maintenance tips to help you get the most out of your A4VSO pump:

Regularly inspect the pump: Regular inspections can help you identify any issues or potential problems with the pump before they become serious. Check for leaks, damage, or wear on the various components of the pump, including the cylinder block, pistons, swash plate, valve plate, shaft seal, bearings, and housing.

Replace worn or damaged parts: If you identify any worn or damaged parts during your inspection, it’s important to replace them promptly with genuine Rexroth replacement parts. Using non-genuine parts can reduce the performance and reliability of the pump.

Use the right hydraulic fluid: It’s important to use the right type of hydraulic fluid for the A4VSO pump. Rexroth recommends using a mineral-based hydraulic fluid that meets ISO 6743-4, HV or HG classification, or a synthetic hydraulic fluid that meets ISO 6743-4, HV or HG classification.

Monitor fluid levels: Check the fluid levels regularly and top up as needed. Low fluid levels can cause the pump to overheat and reduce performance.

Check filters: The A4VSO pump is equipped with filters that help to prevent contamination of the hydraulic fluid. Regularly check and clean or replace the filters as needed to ensure optimal performance.

Follow recommended maintenance schedule: Follow the recommended maintenance schedule for the A4VSO pump, which includes regular inspections, fluid changes, and filter replacement. Regular maintenance can help to extend the life of the pump and prevent downtime.

By following these maintenance tips, you can help to ensure the optimal performance and reliability of your Rexroth A4VSO pump.