Sanitary pads and sanitary napkins are both physiological care tools commonly used by female friends, but many people can’t distinguish the difference between pads and sanitary napkins. So when will we use pads, when will we use sanitary napkins, and what are their functions? Next we will introduce to you.

1. The principle and appearance of sanitary pads and sanitary napkins

In fact, in essence, the principles of sanitary pads and sanitary napkins are the same, and both have the function of absorbing physiological fluids. However, sanitary panty liners are generally not used to absorb menstrual blood, and they are commonly used in daily life, so they are designed to be compact and convenient for people to use.

However, sanitary napkins are generally used during menstruation and need to absorb a lot of physiological fluids. Therefore, from the design point of view, designers will design sanitary napkins to be larger and thicker than hygienic pads, just like an enlarged version of the sanitary pads.

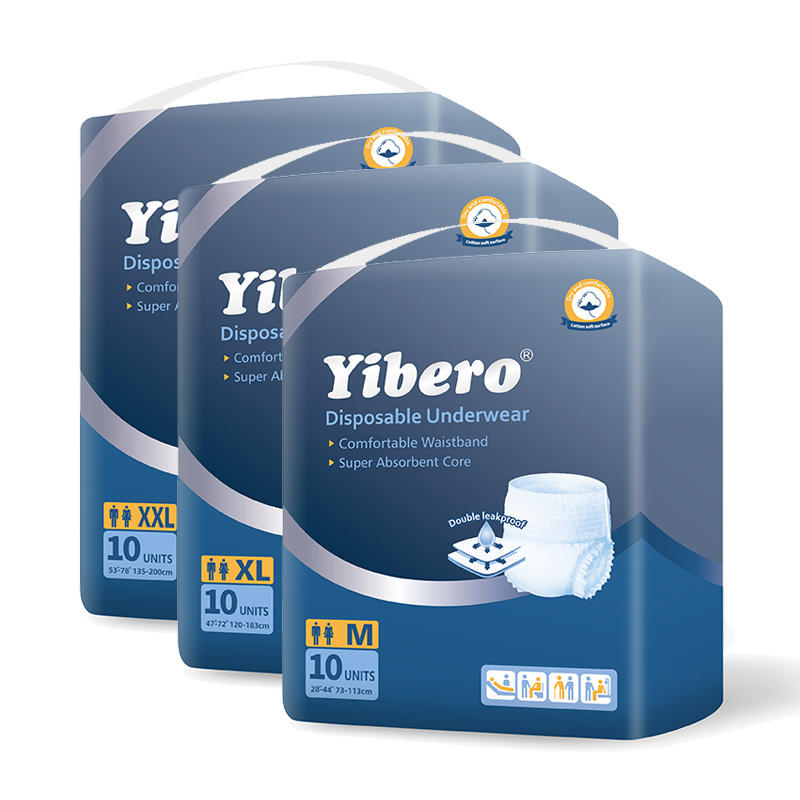

We, as a prfessional company of adult care products, support disposable underpads bulk for the customers, and if you want to buy sanitary pads, please feel free to contact us.

2. The period of use of sanitary napkins and sanitary pads

Generally, we cannot use sanitary pads during menstruation. Because sanitary pads have a relatively small suction volume, menstrual blood can easily leak out and stain our pants.

Therefore, sanitary pads are generally used only when there is more vaginal discharge, and sanitary napkins are divided into daily use and night use. Daily use is generally used during the day, because female friends will have less menstrual blood during the day, and will also change more frequently.

The sanitary napkins used at night are generally relatively large, because the night sleep time is relatively long, and people like to move around when sleeping at night, and the sanitary napkin for night use generally also has the effect of preventing side leakage.